UNDERSTANDING THE COST OF A 3D ROAD MODEL: FACTORS THAT IMPACT PRICE

GPS Machine Control

The increased use of GPS systems for construction projects has led to contractors often asking themselves or service providers like us, “What does a 3d road model cost?”. Typically, you’ll hear the standard reply of “it depends” which it does. However, we’re going to explain why it depends and what each type might generally cost.

Bigger Road Project Means Higher Cost

3d road models provide the data that a GPS-equipped machine will use to provide vertical guidance. Because of this, the key to a successful road project is an accurate 3d model. Different variables factor into the final cost of a 3d road model. Not surprisingly, the two main factors that impact road model pricing are complexity level and road size. Common sense tells us that the more involved and the larger a project is the more expensive it will be, and this is also the case with 3d road models. Imagine a small road in any neighborhood and then picture any state highway. Both are roads, yes, but they are very different in how they’re built which contributes to the price differences related to the road model.

General Cost of 3d Road Model Types

To explain the varying levels of complexity, we’ll cover three common types of road models: edge of pavement (EOP), edge of pavement plus an offset, and a full surface model. These options allow you to fine-tune your model. A large project that is EOP only will not take nearly as long as a fully modeled 3- block city street project with sidewalks on both sides and 30 driveway aprons. Let's further break down the differences between the 3 model types for additional clarity.

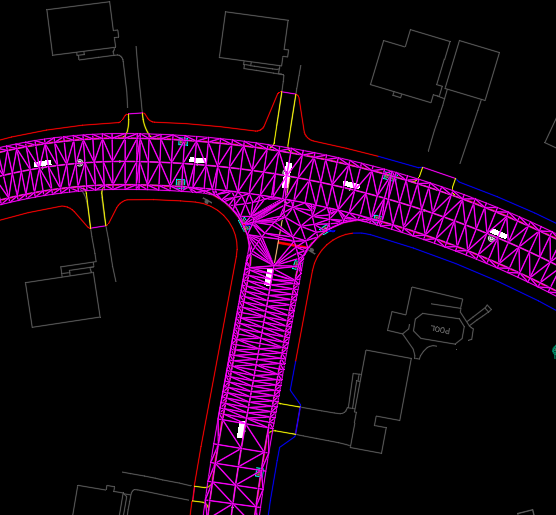

Road Model (Grid)

An edge of pavement model can be as simple as using a horizontal alignment, vertical alignment, and a typical section. These models can be relatively simple to construct and start around $600. EOP models can also use superelevation diagrams, spot grades, contours, and cross-sections if the road has a varying cross-slope. The goal of an EOP model is to accurately model all paved areas within the roadway.

A step up from an EOP model is an EOP+ model. These models build on a basic EOP model by widening the surface a specified amount past the EOP. A typical offset is 3’ past the EOP, this allows for easier grading along the curb line. This can be tricky when the road’s cross-slope varies as the cross-slope of the widened area has to be manually altered by the virtual construction engineer. These projects take time, but they are still much faster to complete than the third model type, the full surface model.

The full surface model for a road project can be very involved. Sidewalks and driveway aprons take the most time to model because they have complex geometries, and the elevations have to be assumed from typical sections. To model the typical driveway apron, you have to first verify where the curb ramps start and end, the curb reveal within the driveway and the slope of the driveway from cross-sections. Rarely does an engineer provide enough elevation data to make this process streamlined.

3d Road Model

Some of the largest full-surface models can take well over 100 hours to complete and cost close to $30,000, although that is highly unusual. More expensive models are usually very large which most often means they are a civil/heavy highway project type. These huge projects typically have plan sets with hundreds of pages that must be combed through. Virtual construction engineers must identify not only profiles and typicals but also cross-sections, roundabouts, daylights, intersections, sidewalks, ADA ramps/compliance, and do a complete overview of the grading plan. In our experience, most road jobs end up costing somewhere within that $600 to $30,000 range with most falling somewhere in between.

Virtual construction engineers that frequently create 3d road models develop a keen eye for all of the details and components that go into the model. By building these regularly, they become knowledgeable in reading the plan sets and identifying issues quickly. Familiarity with ADA compliance comes in handy and turns into value engineering when a potential problem is identified at the time of the model building versus at the time of the final grading. This factor alone creates an excellent argument for the use of 3d road models. The time and money that may have been wasted had the project been initiated without the model adds up quickly. We hope this has helped you get a better understanding of how pricing works on 3d road models but if you want to speak with us about it, give us a call anytime.