AVOID EVERY UTILITY CONTRACTORS’ BIGGEST HEADACHE AND INVEST IN GPS

Imagine it's a Wednesday morning, your crew is out in the field digging a trench for a new water line, and you get a call from one of your operators. “Hey, boss, uhm, there was an issue with the slope.” You ask, “How bad is it?” “6 inches over 200 feet.” Suddenly, your heart sinks at first glance to most people; a few inches of inaccuracy may not seem like a huge deal, but now the mistake is detrimental to the overall project. Now the flow rate is no longer compatible with the measurements of the trench; the water line will not pass inspection, and will delay the time of completion. The mistake is going to burn a hole in your pocket as you will spend a significant amount of money on rework, cutting into your profits. The crew now has to stay late and work overtime, and you spend hours on the phone to reschedule inspections and inform your client of the delay (which can tarnish your relationship). Next thing you know, a simple miscalculation of a few inches has become a huge thorn in your side. What if you were told all this could have been avoided, that investing in GPS technology prevents you from enduring this major headache? GPS machine control technology has gradually been adopted by contractors over the years. Read more to learn about how the emerging trend of technology is being used in utility construction.

Projects that Utility Contractors will use GPS Machine Control on:

Installation of a sewer main

Installation of a gas line

Installation of a communication line

Installation of a water line

Creating trenches for conduit installation in the solar field

Site grading for substations

Moving Utility Lines during highway construction projects

How does GPS machine control increase productivity and save utility contractors money?

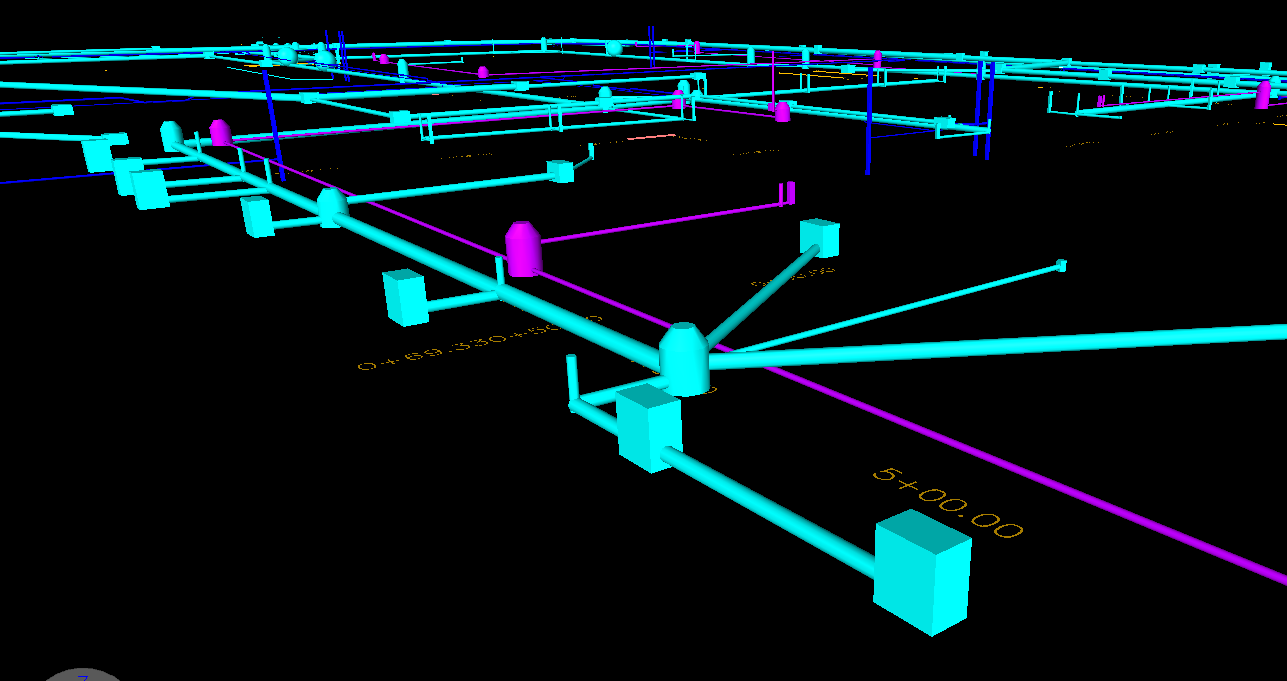

Accurate estimates will win you more bids and provide tangible evidence to customers that you offer clear and transparent communication. The data displayed in 3D models, as-builts, and drone flight data collection provides accurate, measurable, and tangible data that can be used to create compliance reports. This will eliminate inspection delays. GPS can map out proposed utilities and highlight them during the excavation phase, showing the operator the exact location and computing the precise depth they need to cut. Utilizing 3D models allows for trenches to be excavated quickly. If the trench is unsafe, this technology permits you to excavate without requiring an operator to enter the trench and put their life at risk. Our models can include the existing utilities for operators to reference when digging. GPS has an accuracy of within centimeters, which is crucial; if your calculations are off by a couple of inches, you risk striking an existing utility line. This leads not only to project delays and liability claims but also to serious injuries or fatalities. Striking an existing utility line can cause it to leak hazardous materials, and exposure for crews can be dangerous, or exposure to a live electrical utility line can lead to electrocution.

Any size company can use GPS machine control, especially when working on larger commercial projects. Either way, if you can afford the initial investment, your ROI will not disappoint. You’ll clearly see the benefits of this technology through reduced survey costs, decreased rework, and more productivity.

Keep in mind:

GPS technology training will last a few days, but after a few weeks, most field crews will be able to operate the machinery independently with confidence. Eventually, it will become second nature for them. If any issues arise with your data or you have problems with the GPS signal, call your engineer and/or your retailer salesperson. They can walk you through troubleshooting or recalibration. Sometimes it may be as simple as the area you are working in has an element that obstructs the GPS signals; for this technology to work, you need open sky. Before clients hire us for our services, we are willing to share past projects or demos to provide them with enough evidence of our capabilities. We want contractors to make informed decisions and feel confident when choosing us as their modelers.

If you have questions about how GPS machine control benefits utility contractors, reach out to 877-572-3414 or email us at info@eci3d.com!