OWNERSHIP VS RENTAL: FACTORS TO CONSIDER WHEN ACQUIRING HEAVY EQUIPMENT

Got a new project? In a competitive bidding environment, having the right equipment can determine whether or not you win the job. Do you need to replace outdated machines, operate more efficiently within a growing workload, or even meet tight deadlines? Then it might be time to expand your capabilities by adding to your fleet. When you are evaluating ownership, comparing new vs used machines, contemplate looking into rental options. It is crucial to consider the different avenues for acquisition as it is a substantial investment, and you want to guarantee you get the most bang for your buck. In this guide, we break down the advantages and disadvantages of purchasing versus renting equipment, and the advantages and disadvantages of buying new versus used equipment, to ensure you make the most logical and cost-effective decision based on your budget and timeline.

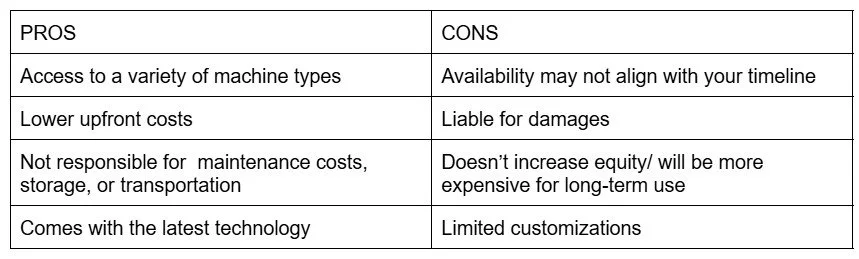

Rental:

Smaller contractors typically own a handful of machines and rent based on projects and their needs. Larger contractors, whose portfolio extends over a large geographical territory, often rent most of their equipment local to the project's location to avoid transportation and storage costs. The best part about rentals is that projects require different types of equipment; renting allows you access to that equipment without the commitment of owning a machine you may not use often.

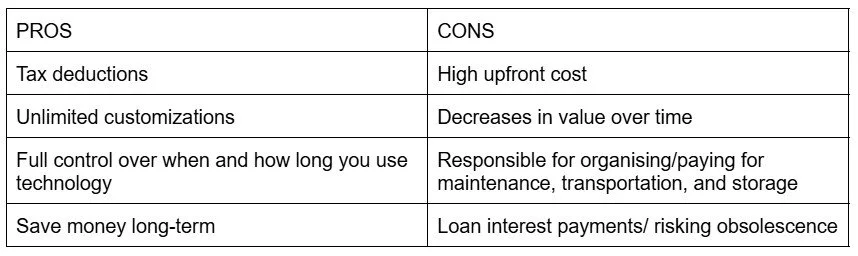

Ownerships:

New vs Used:

If you decide to pursue ownership, the next step is for you to determine whether you want to shop for new or used equipment. The initial investment in new equipment can be very expensive; however, there tend to be more deals offered for new machines. New equipment typically comes with brand-new cutting-edge technology, such as factory-installed smart systems. They are reliable and feature technology that enhances safety in the field. Oftentimes times warranty protection is offered with new equipment, which can be beneficial in the future. New equipment is easy to use, although, depending on the latest technology it comes with, it may require training. Similar to owning a car, over time the value decreases, so if you decide to resell, you will receive less than you paid. Purchasing new equipment is beneficial for large contractors with long-term projects.

If you choose to buy used equipment, it is more affordable initially, as it costs less and has lower insurance rates. There is a variety of used machines to select from, which usually requires less training. Used equipment enables you to expand your fleet quickly, eliminating a huge financial hit to your budget. The cons of buying used equipment include a lack of financing options, a shorter lifespan, and an increase in repair costs. It may also have outdated technology that may not give you a competitive edge.

When making a decision, keep your budget and the scope of your projects in mind. Also factor in your access to maintenance and assess the resale value of your selected equipment and determine whether or not you may want to profit from it down the line. The majority of new machines, whether purchased or rented, have GPS machine control technology built into the equipment. Some used machines may already have GPS installed; it may depend on the age of the equipment and whether the previous owner needed it. Various brands sell heavy equipment with or without GPS technology. Some of the most well-known brands are John Deere, CAT, Komatsu, Hitachi, CASE, and Doosan. All brands are reputable and have great products, so choosing the right one for you will be based on preference. We recommend looking at each brand before making a final decision. Consult your local dealership, and they will be able to provide you with pricing and more information. Prices and rental rates will vary depending on the retailer and brand you choose. Conduct a thorough amount of research to ensure you get the best deal possible.

If you have any questions, want a third-party perspective, or need help selecting a retailer, don’t hesitate to reach out to 877-572-3414 or email us at info@eci3d.com!